How Are Naphthalene Derivatives Used in Surfactant Production?

Nov 14,2025What Role Do Pyrimidine Derivatives Play in Biological Systems?

Nov 07,2025Thiophene Derivatives: Uses, Properties, and Applications

Oct 31,2025How Do Triazine Derivatives Act as Antimicrobial or Antifungal Agents?

Oct 24,2025What Makes Carbazole Derivatives Chemically Stable?

Oct 17,2025In the evolving landscape of advanced materials, polyimide derivatives have carved a distinct niche. Known for their exceptional thermal stability, chemical resistance, and mechanical robustness, these high-performance polymers are redefining the boundaries of material science across a spectrum of industries—from aerospace to electronics, from automotive to medical technology.

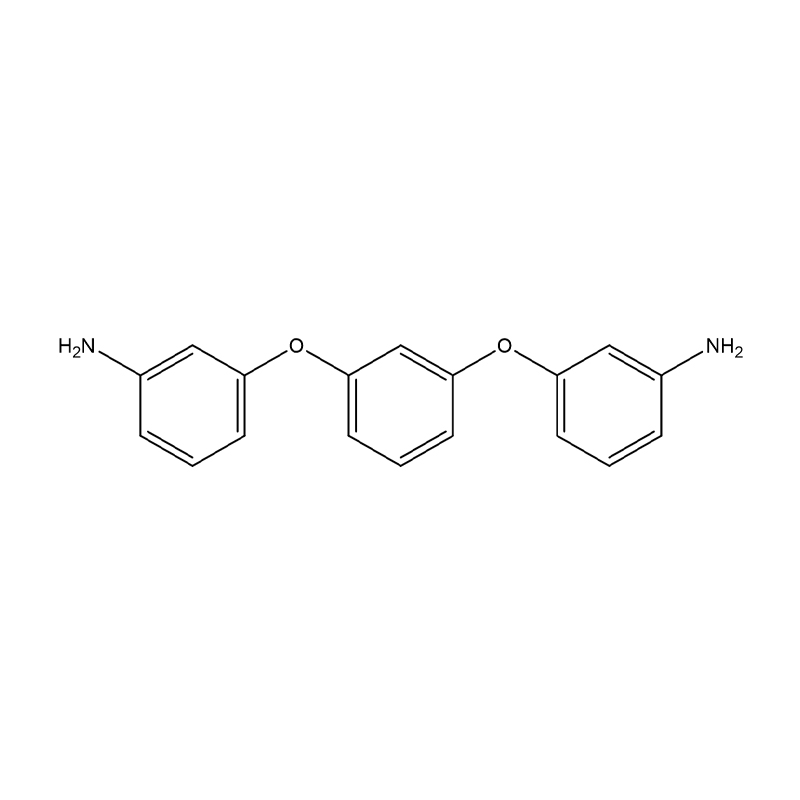

At their core, polyimides are aromatic heterocyclic polymers, formed through the polycondensation of dianhydrides and diamines. But the story doesn't end there. Polyimide derivatives—functionalized or structurally modified versions—take this foundational resilience and amplify it, delivering enhanced properties tailored to specific applications. It’s not just evolution; it’s engineering alchemy.

Precision Engineering at the Molecular Level

What sets polyimide derivatives apart is the ability to fine-tune their molecular architecture. Whether it's incorporating flexible linkages to improve processability or grafting in functional side groups for better compatibility with other substrates, these modifications open a vast landscape of possibilities. Derivatives like fluorinated polyimides offer lower dielectric constants and increased transparency, vital for optoelectronic and 5G applications. Meanwhile, thermoplastic polyimides blend the best of both worlds—retaining high thermal resistance while enabling melt-processability, a rare and valuable trait.

Thermal and Chemical Mastery

Polyimide derivatives thrive under extreme conditions. Many withstand temperatures exceeding 500°F (260°C) without degradation. Their chemical inertness is equally notable; acids, solvents, and oxidizing agents barely ruffle their molecular serenity. This makes them indispensable in environments where lesser materials falter—think spacecraft exteriors, deep-sea sensors, or semiconductor fabrication lines. In such applications, failure is not an option, and polyimide derivatives are the dependable vanguard.

Anisotropic Strength and Dimensional Stability

Beyond thermal and chemical endurance, polyimide derivatives exhibit anisotropic mechanical properties—meaning their strength can be directionally optimized. This is particularly valuable in composite applications where stress distribution matters. Add to this an outstanding dimensional stability—low creep, minimal expansion, and excellent fatigue resistance—and you get a material that performs like an engineering dream.

Application Vistas: Broad, Bold, and Beyond

The applications of polyimide derivatives stretch across a startling array of domains:

Aerospace: Used in lightweight composite materials for structural components, insulation films for wiring, and coatings that must endure the vacuum and radiation of space.

Electronics: Found in flexible printed circuits, interlayer dielectrics, and display substrates, thanks to their thermal reliability and electrical insulation.

Medical Devices: Biocompatible polyimide derivatives enable minimally invasive tools and implantable devices, supporting the human body without inciting immune response.

Automotive: High-performance coatings and sensor insulators keep engine environments operational even under continuous thermal cycling.

The Sustainability Imperative

As industries pivot toward sustainability, polyimide derivatives are evolving in tandem. Bio-based precursors and green synthesis methods are being explored, reducing the environmental impact without compromising performance. Recyclable and reprocessable polyimide variants are beginning to surface, signaling a shift from traditional, single-use paradigms toward circular material economies.

The future of polyimide derivatives lies in convergence—of disciplines, industries, and technologies. As demands grow more exacting, so too will the customization of these materials. Nanocomposites, hybrid laminates, and smart polyimide matrices embedded with sensors are not far-off concepts; they are the next frontier.

In a world increasingly reliant on high-precision, high-performance solutions, polyimide derivatives offer not just durability, but adaptability. They are not merely materials—they are strategic enablers of progress.

Copyright © 2023 Suzhou Fenghua New Material Technology Co., Ltd. All Rights Reserved.

Custom OLED Material Intermediate Manufacturers