How Are Naphthalene Derivatives Used in Surfactant Production?

Nov 14,2025What Role Do Pyrimidine Derivatives Play in Biological Systems?

Nov 07,2025Thiophene Derivatives: Uses, Properties, and Applications

Oct 31,2025How Do Triazine Derivatives Act as Antimicrobial or Antifungal Agents?

Oct 24,2025What Makes Carbazole Derivatives Chemically Stable?

Oct 17,2025In the broad world of industrial chemistry, surfactants play a vital role in nearly every aspect of modern life — from detergents and personal care products to concrete additives, textiles, and agriculture. Behind the chemistry of many high-performing surfactants lies a class of compounds known as Naphthalene Derivatives. These aromatic hydrocarbons, derived from naphthalene, possess a unique structure and reactivity that make them valuable in producing efficient, stable, and multifunctional surfactant systems.

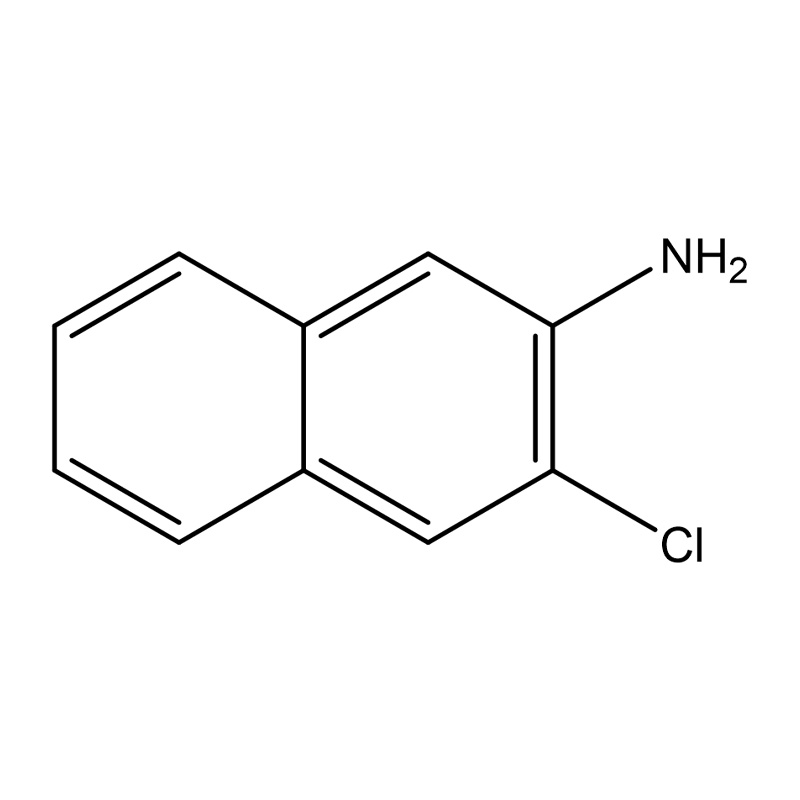

To understand how naphthalene derivatives contribute to surfactant production, it is useful to begin with their molecular foundation. Naphthalene itself is a bicyclic aromatic hydrocarbon composed of two fused benzene rings. When functional groups such as sulfonic acid, hydroxyl, or alkyl chains are introduced to this structure, the resulting compounds are called naphthalene derivatives.

Common naphthalene derivatives used in surfactant chemistry include:

These derivatives serve as the building blocks for anionic surfactants — surfactants that carry a negative charge in aqueous solutions. Their aromatic backbone provides thermal and chemical stability, while the attached hydrophilic groups enhance water solubility and interfacial activity.

Surfactants rely on a balance of hydrophilic (water-loving) and hydrophobic (water-repelling) properties to reduce surface and interfacial tension. Naphthalene derivatives naturally lend themselves to this dual nature because of their aromatic ring structure (hydrophobic) and their substituted polar groups (hydrophilic).

Several factors make these compounds especially useful in surfactant production:

High Surface Activity:

Naphthalene sulfonates effectively lower the surface tension between liquids and solids, improving wetting and emulsifying performance.

Thermal and Chemical Stability:

Their aromatic structure provides resistance to degradation under heat, acidic, or alkaline conditions — making them ideal for industrial applications.

Compatibility with Various Systems:

Naphthalene derivatives are compatible with other surfactants, dispersants, and additives, allowing them to be used in diverse formulations.

Efficient Dispersing Power:

They help suspend solid particles uniformly in liquid media, preventing sedimentation or clumping in mixtures such as concrete or dyes.

Cost-Effectiveness:

Compared with some synthetic alternatives, naphthalene derivatives provide strong performance at relatively moderate production costs.

In surfactant manufacturing, naphthalene derivatives are used primarily as precursors or modifiers that enhance surfactant performance in specific environments. The following sections outline how these derivatives are incorporated into surfactant systems and what functions they serve.

One of the most common uses of naphthalene derivatives is the formation of naphthalene sulfonate surfactants. These compounds are created by sulfonating naphthalene with sulfuric acid or oleum, followed by neutralization with sodium hydroxide or other bases to form the corresponding salt.

Sodium naphthalene sulfonate is a classic example. It acts as an efficient anionic surfactant that provides excellent dispersing and wetting properties. In aqueous systems, the sulfonate group enhances solubility, while the naphthalene ring provides the hydrophobic component necessary for surface activity.

Such surfactants are widely used in:

Many surfactants function not only by reducing surface tension but also by maintaining particle dispersion. Naphthalene derivatives, especially naphthalene sulfonate-formaldehyde condensates (NSF or SNF), are particularly effective as dispersing agents.

During production, naphthalene sulfonic acid reacts with formaldehyde to create a polymeric structure. The resulting product exhibits strong electrostatic repulsion, preventing fine particles from aggregating in aqueous solutions.

This property makes them invaluable in:

By serving as a dispersant, the naphthalene-based surfactant improves product uniformity, efficiency, and appearance, while also extending shelf life.

The ability to stabilize emulsions is another critical role of naphthalene derivatives. Their amphiphilic nature allows them to reduce interfacial tension between immiscible liquids (such as oil and water), creating stable emulsions.

In formulations such as oil-in-water emulsions, lubricant additives, and cleaning agents, naphthalene sulfonates ensure that oil droplets remain evenly distributed. This leads to consistent texture, better cleaning efficiency, and enhanced formulation stability.

As wetting agents, they enable liquids to spread more easily over solid surfaces — an essential characteristic in applications like coatings, agricultural chemicals, and printing inks.

Naphthalene derivatives are also important in emulsion polymerization, a process used to produce synthetic rubber, latex, and coatings. Here, surfactants stabilize monomer droplets and growing polymer particles in water, controlling particle size and preventing coagulation.

Alkyl naphthalene sulfonates are particularly suited for this role. They exhibit low foaming, high stability, and excellent emulsifying ability under varying pH conditions. The result is a finely controlled polymerization process that yields uniform, high-quality products.

Perhaps one of the most well-known commercial applications of naphthalene derivative surfactants is in superplasticizers used in concrete. Sodium naphthalene sulfonate formaldehyde (SNF) superplasticizers significantly improve the flow and workability of concrete without requiring additional water.

By dispersing cement particles uniformly, SNF surfactants reduce the water-to-cement ratio, enhancing the final product’s strength and durability. This application has been instrumental in advancing modern construction techniques and sustainable building materials.

The versatility of naphthalene derivatives means that they appear in many industries where surfactants are needed for dispersion, emulsification, or stabilization. Below are some key sectors where their use is particularly valuable:

| Industry | Function of Naphthalene Derivatives |

| Textile | Leveling agents, dispersants for dyes and pigments |

| Construction | Water reducers, concrete superplasticizers |

| Agriculture | Wetting agents, dispersants in agrochemical formulations |

| Coatings & Paints | Pigment dispersants, anti-settling agents |

| Plastics & Rubber | Emulsion polymerization stabilizers |

| Mining | Flotation agents and ore dispersants |

| Detergent Production | Wetting and emulsifying agents |

Their broad compatibility allows them to be blended with other surfactants, polymers, and additives, enabling manufacturers to tailor formulations for specific performance requirements.

While naphthalene derivatives are highly effective, their aromatic structure also raises questions about biodegradability and toxicity. Pure naphthalene is known to be persistent in the environment and potentially harmful in high concentrations. However, not all naphthalene derivatives share the same risk profile.

Modern production methods and formulations aim to minimize environmental impact through:

As industries transition toward greener chemistries, the challenge lies in balancing performance with environmental responsibility. Researchers are actively exploring bio-based aromatic substitutes and renewable sulfonated compounds as sustainable alternatives to traditional naphthalene-based surfactants.

The ongoing research in naphthalene derivative surfactants reflects the industry’s shift toward innovation and sustainability. Some notable directions include:

These innovations illustrate how traditional chemistry can evolve to meet the demands of modern environmental and performance standards.

Naphthalene derivatives occupy a crucial place in surfactant production due to their robust chemical structure, versatility, and efficiency. From improving the workability of concrete to stabilizing pigments, emulsions, and polymers, these compounds have proven indispensable across numerous industries.

Their combination of aromatic stability and hydrophilic adaptability gives them exceptional dispersing, emulsifying, and wetting capabilities — properties that make them central to the performance of countless formulations.

At the same time, the global chemical industry is working to reduce the environmental footprint associated with naphthalene-based compounds. Ongoing innovations in synthesis, green chemistry, and biodegradability reflect a commitment to maintaining functionality while enhancing safety and sustainability.

In summary, naphthalene derivatives represent both a cornerstone of current surfactant technology and a foundation for future advancements — demonstrating how chemistry continues to evolve in pursuit of cleaner, smarter, and more efficient industrial solutions.

Copyright © 2023 Suzhou Fenghua New Material Technology Co., Ltd. All Rights Reserved.

Custom OLED Material Intermediate Manufacturers